I am utterly enchanted by this venture employing fish skins and nanotechnology-based processes for a new line of skin care products and, they hope, medical applications,

For those who like text (from a May 21, 2018 Sanford media advisory),

Nanofibre magic turns fish skins into wrinkle busting skin care

Sanford partners with kiwi nanotech experts to help develop a wrinkle-busting skincare product made from Hoki skins.

…

New Zealand’s biggest and oldest seafood company is moving into the future of skincare and medicine by becoming supporting partner to West Auckland nanofibre producer Revolution Fibres, which is launching a potentially game-changing nanotech face mask.

The actiVLayr face masks use collagen extracted from fish skins as a base ingredient which is then combined with elements such as fruit extracts and hyaluronic acid to make a 100 percent natural and sustainably sourced product.

They have achieved stunning results in third party tests which show that the nanofiber masks can reduce wrinkles by up to 31.5%.*

Revolution Fibres CEO Iain Hosie says it is no exaggeration to say the masks could be revolutionary.

“The wayactiVLayr is produced, and the unique application method of placing it onto wet skin like a mask, means ingredients are absorbed quickly and efficiently into the skin to maximise the repair and protection of the skin.”

Sanford is delighted to support the work that Revolution Fibres is doing by supplying hoki fish skins. Hoki is a sustainably caught fish and its skin has some unique properties.

…

Sanford’s General Manager of Innovation, Andrew Stanley, says these properties make it ideal for the actiVLayr technology. “Hoki skins are rich in collagen, which is an essential part of our bodies. But their marine collagen is unique – it has a very low melt point, so when placed on the skin, it can dissolve completely and be absorbed in a way that collagen f rom other animals cannot.”

Sanford’s Chief Customer Officer, Andre Gargiulo, says working with the team at Revolution Fibres is a natural fit, because both company’s think about innovation and sustainability in the same way.

“We hope actiVLayr gets the global attention it deserves, and we’re delighted that our sustainably caught Hoki is part of this fantastic New Zealand product. It’s exactly what we’re all about at Sanford – making the most of the precious resources from the sea, working in a sustainable way and getting the most value out of the goodness we harvest from nature.”

Sanford’s Business Development Manager Adrian Grey says the focus on sustainability and value creation are so important for the seafood company.

“Previously we have been making use of these hoki skins, which is great, but they were being used only for fish meal or pet food products. Being able to supply and support a high tech company that is going to earn increased export revenue for New Zealand is just fantastic. And the product created is completely natural, harvested from a globally certified sustainable fishery.”

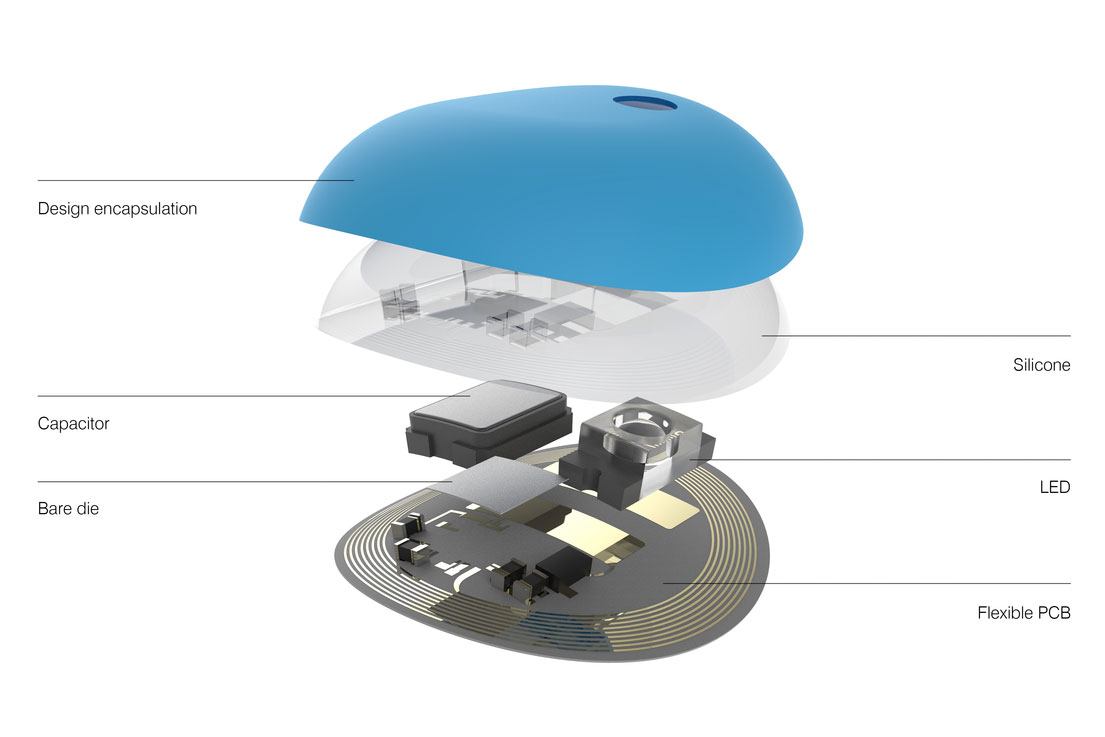

Sanford provides the hoki skins and then turns these skins into pure collagen using the science and skills of the team at Plant and Food in Nelson [New Zealand for those of us who associate Nelson with British Columbia]. Revolution Fibres transforms the Sanford product into nanofibre using a technique called electrospinning of which Revolution Fibres are the New Zealand pioneers.

During the electrospinning process natural ingredients known as “bioactives” (such as kiwifruit and grapes) and hyaluronic acid (an ingredient to help the skin retain moisture) are bonded to the nanofibres to create sheets of actiVLayr. When it is exposed to wet skin the nanofibres dissolve rapidly and release the bioactives deep into the skin.

The product is being launched at the China Beauty Fair in Shanghai on May 22 [2018] and will go on sale in China this month followed by Hong Kong and New Zealand later in the year. Revolution Fibres CEO Iain Hosie says there is big demand for unique delivery systems of natural skin and beauty products such as actiVLayr in Asia, which was the key reason to launch the product in China. But his view of the future is even bigger.

“There are endless uses for actiVLayr and the one we’re most proud of is in the medical area with the ability for drug compounds or medicines to be added to the actiVLayr formula. It will enable a controlled dose to be delivered to a patient with skin lesions, burns or acne.”

Revolution Fibres is presenting at Techweek NZ as part of The Fourth Revolution event on May 25 [2018] in Christchurch which introduces high tech engineers who are building a better place.

*Testing conducted by Easy Care using VISIA Complexion Analysis

The media advisory also includes some ‘fascinating ‘facts’,

1kg of hoki skin produces 400 square meters of nanofibre material

Nanofibres are 1/500th the width of a human hair

Revolution Fibres is the only nanofibre producer in the world to meet aerospace industry standards with its AS9100d quality assurance certification

The marine collagen found in hoki skins is unique because of its relatively low melt point, meaning it can dissolve at a lower temperature which makes it perfect for human use

Revolution Fibres is based in West Auckland and employs 12 people, of which 4 have P hDs in science related to nanotechnology. There are also a number of employees with strong engineering backgrounds to complement the company’s Research & Development expertise

Sanford is New Zealand’s oldest and biggest seafood company. It was founded by Albert Sanford in Auckland in 1904

New Zealand’s hoki fishery is certified as sustainable by the London-based Marine Stewardship Council, which audits fisheries all over the world

You can find Sanford here and Revolution Fibres here.

For some perspective on the business side of things, there’s a May 21, 2018 article by Nikki Mandow for newsroom.co.nz,

…

Revolution Fibres first started talking about the possibility of a collagen nanofibre made from hoki almost a decade ago, as part of a project with Plant & Food’s Seafood Research Centre in Nelson, Hosie [Revolution Fibres CEO Iain Hosie] said, and the company got serious about making a product in 2013.

Previously, the hoki waste skins were used for fish meal and pet food, said Sanford business development manager Adrian Grey.

“Being able to supply and support a high tech company that is going to earn increased export revenue for New Zealand is just fantastic.”

Revolution Fibres also manufactures nanofibres for a number of other uses. These include anti-dust mite pillow coverings, anti-pollution protective face masks, filters for pumps for HRV’s home ventilation systems, and reinforcing material for carbon fibre for fishing rods. The latter product is made from recycled fishing nets collected from South America.

…

He [Revolution Fibres CEO Iain Hosie] said the company could be profitable, but instead has chosen to continue to invest heavily in research and development.

About 75 percent of revenue comes from selling proprietary products, but increasingly Hosie said the company is working on “co-innovation” projects, where Revolution Fibres manufactures bespoke materials for outside companies.

Revolution Fibres completed its first external funding round last year, raising $1.5 million from the US, and it has just completed another round worth approximately $1million. Hosie, one of the founders, still holds around 20 percent of the company.

He said he hopes to keep the intellectual property in New Zealand, although manufacturing of some products is likely to move closer to their markets – China and the US potentially. However, he said actiVLayr manufacture will remain in New Zealand, because that’s where the raw hoki comes from.

I wonder if we’ll see this product in Canada.

One other thing, I was curious about this ” … the nanofiber masks can reduce wrinkles by up to 31.5%” and Visia Complexion Analysis, which is a product from Canfield Scientific, a company specializing in imaging. Here’s some of what Visia can do (from the Visia product page),

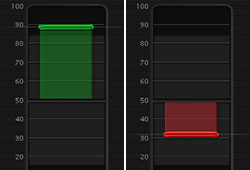

Percentile Scores

VISIA’s patented comparison to norms analysis uses the world’s largest skin feature database to grade your patient’s skin relative to others of the same age and skin type. Measure spots, wrinkles, texture, pores, UV spots, brown spots, red areas, and porphyrins.

Meaningful Comparisons

Compare results side by side for any combination of views, features or time points, including graphs and numerical data. Zoom and pan images in tandem for clear and easy comparisons.

And, there’s my personal favourite (although it has nothing to do with the topic of this posting0,

Eyelash Analysis

Evaluates the results of lash improvement treatments with numerical assessments and graphic visualizations.

For anyone who wondered about why the press release has both ‘nanofibre’ and ‘nanofiber’, It’s the difference between US and UK spelling. Perhaps the complexion analysis information came from a US company or one that uses US spellings.

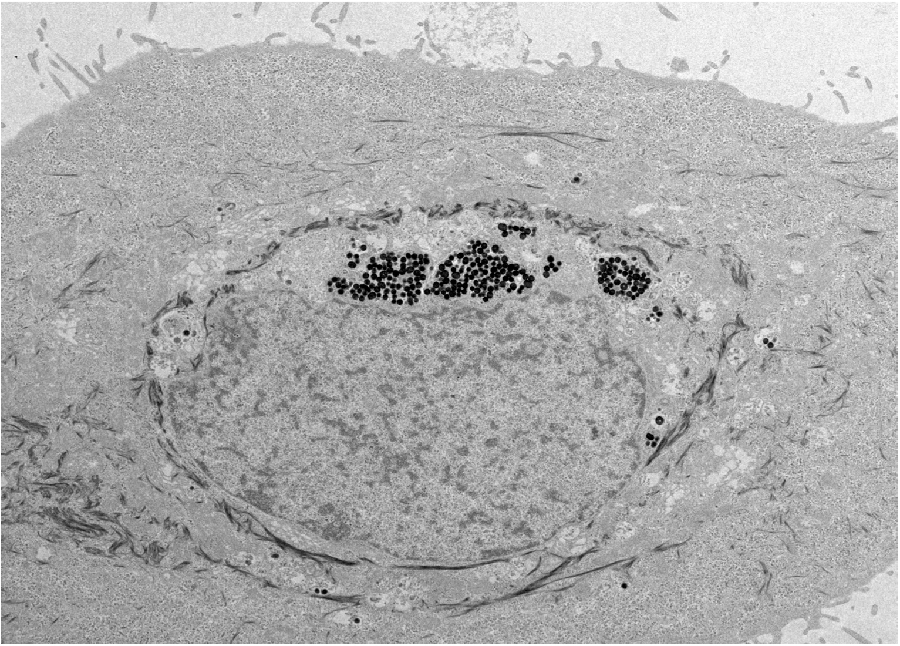

The scientists found that the synthetic nanoparticles were taken up in tissue culture by keratinocytes, the predominant cell type found in the epidermis, the outer layer of skin. Photo by Yuran Huang and Ying Jones/UC San Diego

The scientists found that the synthetic nanoparticles were taken up in tissue culture by keratinocytes, the predominant cell type found in the epidermis, the outer layer of skin. Photo by Yuran Huang and Ying Jones/UC San Diego