Health, safety, and risks have been an important discussion where nanotechnology is concerned. The sense of urgency and concern has died down somewhat but scientists and regulators continue with their risk analysis.

SUN (Sustainable Nanotechnologies) project

Back in a December 7, 2016 posting I mentioned the Sustainable Nanotechnologies (SUN) project and its imminent demise in 2017. A February 26, 2018 news item on Nanowerk announces a tool developed by SUN scientists and intended for current use,

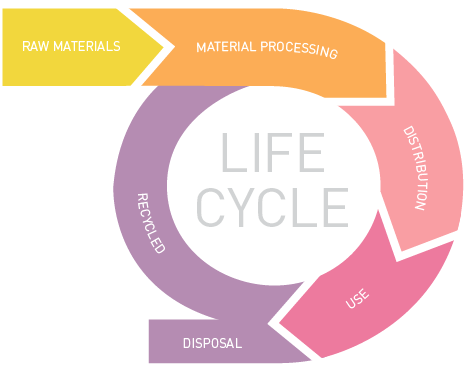

Over 100 scientists from 25 research institutions and industries in 12 different European Countries, coordinated by the group of professor Antonio Marcomini from Ca’ Foscari University of Venice, have completed one of the first attempts to understand the risks nanomaterials carry throughout their life-cycle, starting from their fabrication and ending in being discarded or recycled.

From nanoscale silver to titanium dioxide for air purification, the use of nanomaterials of high commercial relevance proves to have clear benefits as it attracts investments, and raises concerns. ‘Nano’ sized materials (a nanometre is one millionth of a millimetre) could pose environmental and health risks under certain conditions. The uncertainties and insufficient scientific knowledge could slow down innovation and economic growth.

How do we evaluate these risks and take the appropriate preventative measures? The answer comes from the results of the Sustainable Nanotechnologies Project (SUN), which has been given 13 million euros of funding from the European Commission.

Courtesy: SUN Project

A February 26, 2018 Ca’ Foscari University of Venice press release describes some of the SUN project’s last t initiatives including, https://sunds.gd/ or the ‘SUNDS; Decision support system for risk management of engineered nanomaterials and nano-enabled products’,

After 3 years of research in laboratories and in contact with industrial partners, the scientists have processed, tested and made available an online platform (https://sunds.gd/) that supports industries and control and regulating institutions in evaluating potential risks that may arise for the production teams, for the consumers and for the environment.

The goal is to understand the extent to which these risks are sustainable, especially in relation to the traditional materials available, and to take the appropriate preventative measures. Additionally, this tool allows us to compare risk reduction costs with the benefits generated by this innovative product, while measuring its possible environmental impact.

Danail Hristozov, the project’s principal investigator from the Department of Environmental Sciences, Informatics and Statistics at Ca’ Foscari, commented: “The great amount of work done for developing and testing the methods and tools for evaluating and managing the risks posed by nanomaterials has not only generated an enormous amount of new scientific data and knowledge on the potential dangers of different types of nanomaterials, but has also resulted in key discoveries on the interactions between nanomaterials and biological or ecological systems and on their diffusion, on how they work and on their possible adverse consequences. These results, disseminated in over 140 research papers, have been immediately taken up by industries and regulators and will inevitably have great impact on developing safer and more sustainable nanotechnologies and on regulating their risks”.”.

The SUN project has also composed a guide for the safest products and processes, published on its website: www.sun.fp7.eu.

Studied Materials

Scientists have focused their research on specific materials and their us, in order to analyse the entire life cycle of the products. Two of the best-known were chosen: nanoscale silver that is used in textiles, and multi-walled carbon nanotubes that is used in marine coatings and automotive parts. Less known materials that are of great relevance for their use were also included: car pigments and silica anticaking agents used by food industry.

Lastly, SUN included nanomaterials of high commercial value which are extremely innovative: Nitrogen doped Titanium Dioxide for air purification is a new product enabled by SUN and exploited by the large colour ceramics company Colorobbia. The copper based coating and impregnation for wood protection has been re-oriented based on SUN safety assessment, and the Tungsten Carbide based coatings for paper mills is marketed based on SUN results.

You can find out more about the SUN project here and about ‘SUNDS; Decision support system for risk management of engineered nanomaterials and nano-enabled products’ here.

Belgium’s nanomaterials reigster

A February 26, 2018 Nanowerk Spotlight article by Anthony Bochon has a rather acerbic take on Belgium’s efforts to regulate nanomaterials with a national register,

In Alice’s Adventures in Wonderland, the White Rabbit keeps saying “Oh dear! Oh dear! I shall be too late.” The same could have been said by the Belgian federal government when it adopted the Royal Decree of 22nd December 2017, published in the annexes of the Belgian Official Gazette of 15th January 2018 (“Amending Royal Decree”), whose main provisions retroactively enter into force on 31st December 2016. …

The Belgian federal government unnecessarily delayed the adoption of the Amending Royal Decree until December 2017 and published it only mid-January 2018. It creates legal uncertainty where it should have been avoided. The Belgian nanomaterials register (…) symbolizes a Belgian exceptionalism in the small world of national nanomaterials registers. Unlike France, Denmark and Sweden, Belgium decided from the very beginning to have three different deadlines for substances, mixtures and articles.

In an already fragmented regulatory landscape (with 4 EU Member States having their own national nanomaterials register and 24 EU Member States which do not have such registration requirements), the confusion around the deadline for the registration of mixtures in Belgium does not allow the addressees of the legal obligations to comply with them.

…

Even though failure to properly register substances – and now mixtures – within the Belgian nanomaterials register exposes the addressees of the obligation to criminal penalties, the function of the register remains purely informational.

The data collected through the registration was meant to be used to identify the presence of manufactured nanomaterials on the Belgian market, with the implicit objective of regulating the exposure of workers and consumers to these nanomaterials. The absence of entry into force of the provisions relating to the registration of articles is therefore incoherent and should question the relevance of the whole Belgian registration system.

…

Taking into account the author’s snarkiness, Belgium seems to have adopted (knowingly or unknowingly) a chaotic approach to registering nanomaterials. For anyone interesting in the Belgian’ nanoregister’, there’s this September 3, 2014 posting featuring another Anthony Bochon article on the topic and for anyone interested in Bochon’s book, there’s this August 15, 2014 posting (Note: his book, ‘Nanotechnology Law & Guidelines: A Practical Guide for the Nanotechnology Industries in Europe’, seems to have been updated [there is a copyright date of 2019 in the bibliographic information on the publisher’s website]).