It’s interesting to see scientists take science fiction and use it as inspiration; something which I think happens more often than we know. After all, when someone asks where you got an idea, it can be difficult to track down the thought process that started it all.

Scientists at Virginia Tech (Virginia Polytechnic Institute and State University) are looking for a new source of inspiration after offering a close examination of how insect-size superheroes, Ant-Man and the Wasp might breathe. From a December 11, 2018 news item on phys.org (Note: A link has been removed),

Max Mikel-Stites and Anne Staples were searching for a sequel.

This summer, Staples, an associate professor in the Department of Biomedical Engineering and Mechanics in the College of Engineering, and graduate student Mikel-Stites published a paper in the inaugural issue of the Journal of Superhero Science titled, “Ant-Man and the Wasp: Microscale Respiration and Microfluidic Technology.”Now, they needed a new hero.

The two were working with a team of graduate students, brainstorming who could be the superhero subject for their next scientific inquiry. Superman? Batgirl? Aquaman?

Mikel-Stites lobbied for an investigation of Dazzler’s sonoluminescent powers. Staples was curious how Mera, The Princes sof Atlantis, used her hydrokinetic powers.

It turns out, comic books are a great inspiration for scientific discovery.

This month, Mikel-Stites is presenting the findings of their paper at the American Physical Society’s Division of Fluid Dynamics meeting.

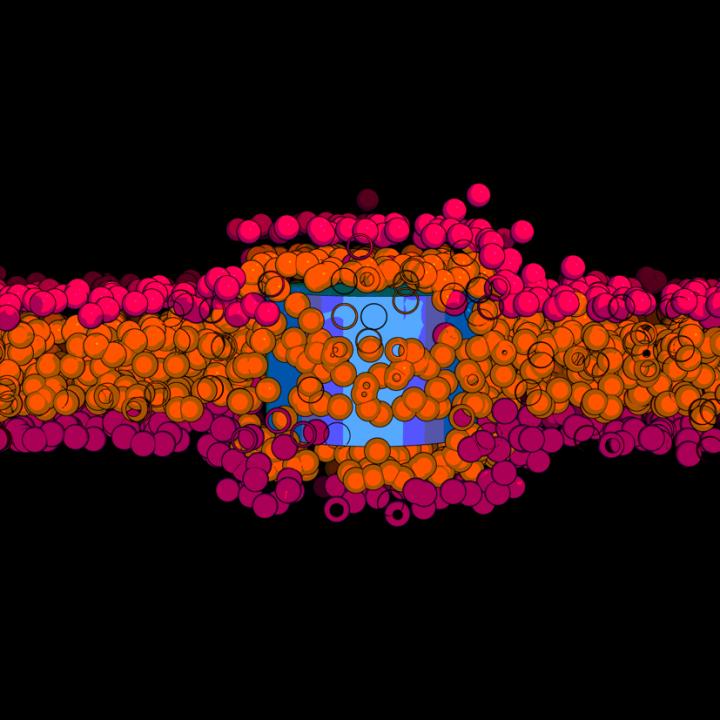

The wonder team’s paper looked at how Ant-Man and the Wasp breathe when they shrink down to insect-size and Staples’ lab studied how fluids flow in nature. Insects naturally move fluids and gases efficiently at tiny scales. If engineers can learn how insects breathe, they can use the knowledge to invent new microfluidic technologies.

A November 2018 Virginia Tech news release (also on EurekAlert but published on December 11, 2018) by Nancy Dudek describes the ‘Ant-Man and Wasp respiratory project’ before revealing the inspiration for the team’s new project,

“Before the 2018 ‘Ant-Man and the Wasp’ movie, my lab was already wondering about insect-scale respiration,” said Staples. “I wanted to get people to appreciate different breathing mechanisms.”

For most of Mikel-Stites’ life, he had been nit-picking at the “science” in science-fiction movies.

“I couldn’t watch ‘Armageddon’ once they got up to space station Mir and there was artificial gravity. Things like that have always bothered me. But for ‘Ant-Man and the Wasp’ it was worse,” he said.

Staples and Mikel-Stites decided to join forces to research Ant-Man’s microscale respiration.

Mikel-Stites was stung by what he dubbed “the altitude problem or death-zone dilemma.” For Ant-Man and the Wasp to shrink down to insect size and still breathe, they would have to overcome an atmospheric density similar to the top of Mt. Everest. Their tiny bodies would also require higher metabolisms. For their survival, the Marvel comic universe had to give Ant-Man and the Wasp superhero technologies.

“I thought it would be fun to find a solution for how this small-scale respiration would work,”said Mikel-Stites.”I started digging through Ant-Man’s history. I looped through scenes in the 2015 movie where we could address the physics. Then I did the same thing with trailers from the 2018 movie. I used that to make a list of problems and a list of solutions.”

Ant-Man and the Wasp solve the altitude problem with their superhero suits. In their publication, Mikel-Stites and Staples write that the masks in Ant-Man and the Wasp’s suits contain “a combination of an air pump, a compressor, and a molecular filter including Pym particle technology,” that allows them to breathe while they are insect-sized.

“This publication showed how different physics phenomena can dominate at different size scales, how well-suited organisms are for their particular size, and what happens when you start altering that,” said Mikel-Stites. “It also shows that Hollywood doesn’t always get it right when it comes to science!”

Their manuscript was accepted by the Journal of Superhero Science before the release of the sequel, “Ant-Man and the Wasp.” Mikel-Stites was concerned the blockbuster might include new technologies or change Ant-Man’s canon. If the Marvel comic universe changed between the 2015 ‘Ant-Man’ movie and the sequel, their hypotheses would be debunked and they would be forced to retract their paper.

“I went to the 2018 movie before the manuscript came out in preprint so that if the movie contradicted us we could catch it. But the 2018 movie actually supported everything we had said, which was really nice,” said Mikel-Stites. Most moviegoers simply watched the special effects and left the theater entertained. But Mikel-Stitesleft the movie with confirmation of the paper’s hypotheses.

The Staples lab members are not the only ones interested in tiny technologies. From lab-on-a-chip microfluidic devices to nanoparticles that deliver drugs directly to cells, consumers will ultimately benefit from this small scientific field that delivers big results.

“In both the movies and science, shrinking is a common theme and has been for the last 50-60 years. This idea is something that we all like to think about. Given enough time, we can reach the point where science can take it from the realms of magic into something that we actually have an explanation for,” Mikel-Stites said.

In fact, the Staples lab group has already done just that.

While Mikel-Stites is presenting his superhero science at the APS meeting, his colleague Krishnashis Chatterjee, who recently completed his Ph.D. in engineering mechanics will be presenting his research on fabricating and testing four different insect-inspired micro-fluidic devices.

From fiction to function, the Staples lab likes to have fun along the way.

“I think that it is really important to connect with people and be engaged in science with topics they already know about. With this superhero science paper I wanted to support this mission,” Staples said.

And who did the lab mates choose for their next superhero science subject? The Princess of Atlantis, Mera. They hope they can publish another superhero science paper that really makes waves.

Here’s a link to and a citation for the paper,

Ant-Man and The Wasp: Microscale Respiration and Microfluidic Technology by Anne Staples and Maxwell Mikel-Stites. Superhero Science and Technology (SST) Vol 1 No 1 (2018): https://doi.org/10.24413/sst.2018.1.2474 July 2018 ISSN 2588-7637

This paper is open access.

And, just because the idea of a superhero science journal tickles my fancy, here’s a little more from the journal’s About webpage,

Serial title

Superhero Science and TechnologFocus and Scope

Superhero Science and Technology (SST) is multi-disciplinary journal that considers new research in the fields of science, technology, engineering and ethics motivated and presented using the superhero genre.The superhero genre has become one of the most popular in modern cinema. Since the 2000 film X-Men, numerous superhero-themed films based on characters from Marvel Comics and DC Comics have been released. Films such as The Avengers, Iron Man 3, Avengers: Age of Ultron and Captain America: Civil War have all earned in excess of $1 billion dollars at the box office, thus demonstrating their relevance in modern society and popular culture.

Of particular interest for Superhero Science and Technology are articles that motivate new research by using the platform of superheroes, supervillains, their superpowers, superhero/supervillain exploits in Hollywood blockbuster films or superhero/supervillain adventures from comic books. Articles should be written in a manner so that they are accessible to both the academic community and the interested non-scientist i.e. general public, given the popularity of the superhero genre.

Dissemination of content using this approach provides a potential for the researcher to communicate their work to a larger audience, thus increasing their visibility and outreach within and outside of the academic domain.

The scope of the journal includes but is not limited to:

Genetic editing approaches;

Innovations in the field of robotics;

New and advanced materials;

Additive Manufacturing i.e. 3D printing, for both bio and non-bio applications;

Advancements in bio-chemical processing;

Biomimicry technologies;

Space physics, astrophysical and cosmological research;

Developments in propulsion systems;

Responsible innovation;

Ethical issues pertaining to technologies and their use for human enhancement or augmentation.Open Access Policy

SST is licensed under a Creative Commons Attribution 4.0 International (CC BY 4.0) licence. You are free to use the work, but you have to attribute (refer to) the work in the manner specified by the author or licensor (but not in any way that suggests that they endorse you or your use of the work). The easiest way to refer to an article is to use the HOWTO CITE tool that you’ll find alongside each article in the right sidebar.…

I also looked up the editorial team, from the journal’s Editorial Team webpage,

Editor-in-Chief

Dr. Barry W. Fitzgerald, TU Delft, the Netherlands

Editorial Board

Prof. Wim Briels, University of Twente, the Netherlands

Dr. Ian Clancy, University of Limerick, Ireland

Dr. Neil Clancy, University College London, UK

Dr. Tom Hunt, University of Kent, UK

Ass. Prof. Johan Padding, TU Delft, the Netherlands

Ass. Prof. Aimee van Wynsberghe, TU Delft, the Netherlands

Prof. Ilja Voets, TU Eindhoven, the Netherlands

For anyone unfamiliar with the abbreviation, TU stands for University of Technology or Technische Universiteit in Dutch.