I’ve been hearing about Mildred Dresselhaus, professor emerita (retired professor) at the Massachusetts Institute of Technology (MIT), just about as long as I’ve been researching and writing about nanotechnology (about 10 years total* including the work for my master’s project with the almost eight years on this blog).

She died on Monday, Feb. 20, 2017 at the age of 86 having broken through barriers for those of her gender, barriers for her subject area, and barriers for her age.

Mark Anderson in his Feb. 22, 2017 obituary for the IEEE (Institute of Electrical and Electronics Engineers) Spectrum website provides a brief overview of her extraordinary life and accomplishments,

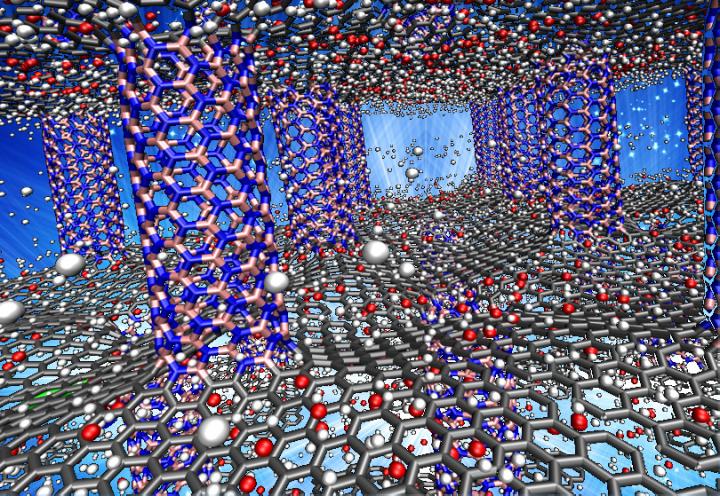

Called the “Queen of Carbon Science,” Dresselhaus pioneered the study of carbon nanostructures at a time when studying physical and material properties of commonplace atoms like carbon was out of favor. Her visionary perspectives on the sixth atom in the periodic table—including exploring individual layers of carbon atoms (precursors to graphene), developing carbon fibers stronger than steel, and revealing new carbon structures that were ultimately developed into buckyballs and nanotubes—invigorated the field.

“Millie Dresselhaus began life as the child of poor Polish immigrants in the Bronx; by the end, she was Institute Professor Emerita, the highest distinction awarded by the MIT faculty. A physicist, materials scientist, and electrical engineer, she was known as the ‘Queen of Carbon’ because her work paved the way for much of today’s carbon-based nanotechnology,” MIT president Rafael Reif said in a prepared statement.

Friends and colleagues describe Dresselhaus as a gifted instructor as well as a tireless and inspired researcher. And her boundless generosity toward colleagues, students, and girls and women pursuing careers in science is legendary.

…

In 1963, Dresselhaus began her own career studying carbon by publishing a paper on graphite in the IBM Journal for Research and Development, a foundational work in the history of nanotechnology. To this day, her studies of the electronic structure of this material serve as a reference point for explorations of the electronic structure of fullerenes and carbon nanotubes. Coauthor, with her husband Gene Dresselhaus, of a leading book on carbon fibers, she began studying the laser vaporation of carbon and the “carbon clusters” that resulted. Researchers who followed her lead discovered a 60-carbon structure that was soon identified as the icosahedral “soccer ball” molecular configuration known as buckminsterfullerene, or buckyball. In 1991, Dresselhaus further suggested that fullerene could be elongated as a tube, and she outlined these imagined objects’ symmetries. Not long after, researchers announced the discovery of carbon nanotubes.

When she began her nearly half-century career at MIT, as a visiting professor, women consisted of just 4 percent of the undergraduate student population. So Dresselhaus began working toward the improvement of living conditions for women students at the university. Through her leadership, MIT adopted an equal and joint admission process for women and men. (Previously, MIT had propounded the self-fulfilling prophecy of harboring more stringent requirements for women based on less dormitory space and perceived poorer performance.) And so promoting women in STEM—before it was ever called STEM—became one of her passions. Serving as president of the American Physical Society, she spearheaded and launched initiatives like the Committee on the Status of Women in Physics and the society’s more informal committees of visiting women physicists on campuses around the United States, which have increased the female faculty and student populations on the campuses they visit.

If you have the time, please read Anderson’s piece in its entirety.

One fact that has impressed me greatly is that Dresselhaus kept working into her eighties. I featured a paper she published in an April 27, 2012 posting at the age of 82 and she was described in the MIT write up at the time as a professor, not a professor emerita. I later featured Dresselhaus in a May 31, 2012 posting when she was awarded the Kavli Prize for Nanoscience.

It seems she worked almost to the end. Recently, GE (General Electric) posted a video “What If Scientists Were Celebrities?” starring Mildred Dresselhaus,

H/t Mark Anderson’s obituary Feb. 22, 2017 piece. The video was posted on Feb. 8, 2017.

Goodbye to the Queen of Carbon!

*The word ‘total’ added on March 14, 2022.