The American Chemical Society (ACS) and the Massachusetts Institute of Technology (MIT) have both issued news releases about the latest in bioluminescence.The researchers tested their work on watercress, a vegetable that was viewed in almost sacred terms in my family; it was not easily available in Vancouver (Canada) when I was child.

My father would hunt down fresh watercress by checking out the Chinese grocery stores. He could spot the fresh stuff from across the street while driving at 30 miles or more per hour. Spotting it entailed an immediate hunt for parking (my father hated to pay so we might have go around the block a few times or more) and a dash out of the car to ensure that he got his watercress before anyone else spotted it. These days it’s much more easily available and, thankfully, my father has passed on so he won’t have to think about glowing watercress.

Getting back to bioluninescent vegetable research, the American Chemical Society’s Dec. 13, 2017 news release on EurekAlert (and as a Dec. 13, 2017 news item on ScienceDaily) makes the announcement,

The 2009 film “Avatar” created a lush imaginary world, illuminated by magical, glowing plants. Now researchers are starting to bring this spellbinding vision to life to help reduce our dependence on artificial lighting. They report in ACS’ journal Nano Letters a way to infuse plants with the luminescence of fireflies.

Nature has produced many bioluminescent organisms, however, plants are not among them. Most attempts so far to create glowing greenery — decorative tobacco plants in particular — have relied on introducing the genes of luminescent bacteria or fireflies through genetic engineering. But getting all the right components to the right locations within the plants has been a challenge. To gain better control over where light-generating ingredients end up, Michael S. Strano and colleagues recently created nanoparticles that travel to specific destinations within plants. Building on this work, the researchers wanted to take the next step and develop a “nanobionic,” glowing plant.

The team infused watercress and other plants with three different nanoparticles in a pressurized bath. The nanoparticles were loaded with light-emitting luciferin; luciferase, which modifies luciferin and makes it glow; and coenzyme A, which boosts luciferase activity. Using size and surface charge to control where the sets of nanoparticles could go within the plant tissues, the researchers could optimize how much light was emitted. Their watercress was half as bright as a commercial 1 microwatt LED and 100,000 times brighter than genetically engineered tobacco plants. Also, the plant could be turned off by adding a compound that blocks luciferase from activating luciferin’s glow.

Here’s a video from MIT detailing their research,

A December 13, 2017 MIT news release (also on EurekAlert) casts more light on the topic (I couldn’t resist the word play),

Imagine that instead of switching on a lamp when it gets dark, you could read by the light of a glowing plant on your desk.

MIT engineers have taken a critical first step toward making that vision a reality. By embedding specialized nanoparticles into the leaves of a watercress plant, they induced the plants to give off dim light for nearly four hours. They believe that, with further optimization, such plants will one day be bright enough to illuminate a workspace.

“The vision is to make a plant that will function as a desk lamp — a lamp that you don’t have to plug in. The light is ultimately powered by the energy metabolism of the plant itself,” says Michael Strano, the Carbon P. Dubbs Professor of Chemical Engineering at MIT and the senior author of the study

This technology could also be used to provide low-intensity indoor lighting, or to transform trees into self-powered streetlights, the researchers say.

MIT postdoc Seon-Yeong Kwak is the lead author of the study, which appears in the journal Nano Letters.

Nanobionic plants

Plant nanobionics, a new research area pioneered by Strano’s lab, aims to give plants novel features by embedding them with different types of nanoparticles. The group’s goal is to engineer plants to take over many of the functions now performed by electrical devices. The researchers have previously designed plants that can detect explosives and communicate that information to a smartphone, as well as plants that can monitor drought conditions.

Lighting, which accounts for about 20 percent of worldwide energy consumption, seemed like a logical next target. “Plants can self-repair, they have their own energy, and they are already adapted to the outdoor environment,” Strano says. “We think this is an idea whose time has come. It’s a perfect problem for plant nanobionics.”

To create their glowing plants, the MIT team turned to luciferase, the enzyme that gives fireflies their glow. Luciferase acts on a molecule called luciferin, causing it to emit light. Another molecule called co-enzyme A helps the process along by removing a reaction byproduct that can inhibit luciferase activity.

The MIT team packaged each of these three components into a different type of nanoparticle carrier. The nanoparticles, which are all made of materials that the U.S. Food and Drug Administration classifies as “generally regarded as safe,” help each component get to the right part of the plant. They also prevent the components from reaching concentrations that could be toxic to the plants.

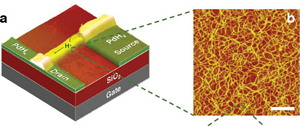

The researchers used silica nanoparticles about 10 nanometers in diameter to carry luciferase, and they used slightly larger particles of the polymers PLGA and chitosan to carry luciferin and coenzyme A, respectively. To get the particles into plant leaves, the researchers first suspended the particles in a solution. Plants were immersed in the solution and then exposed to high pressure, allowing the particles to enter the leaves through tiny pores called stomata.

Particles releasing luciferin and coenzyme A were designed to accumulate in the extracellular space of the mesophyll, an inner layer of the leaf, while the smaller particles carrying luciferase enter the cells that make up the mesophyll. The PLGA particles gradually release luciferin, which then enters the plant cells, where luciferase performs the chemical reaction that makes luciferin glow.

The researchers’ early efforts at the start of the project yielded plants that could glow for about 45 minutes, which they have since improved to 3.5 hours. The light generated by one 10-centimeter watercress seedling is currently about one-thousandth of the amount needed to read by, but the researchers believe they can boost the light emitted, as well as the duration of light, by further optimizing the concentration and release rates of the components.

Plant transformation

Previous efforts to create light-emitting plants have relied on genetically engineering plants to express the gene for luciferase, but this is a laborious process that yields extremely dim light. Those studies were performed on tobacco plants and Arabidopsis thaliana, which are commonly used for plant genetic studies. However, the method developed by Strano’s lab could be used on any type of plant. So far, they have demonstrated it with arugula, kale, and spinach, in addition to watercress.

For future versions of this technology, the researchers hope to develop a way to paint or spray the nanoparticles onto plant leaves, which could make it possible to transform trees and other large plants into light sources.

“Our target is to perform one treatment when the plant is a seedling or a mature plant, and have it last for the lifetime of the plant,” Strano says. “Our work very seriously opens up the doorway to streetlamps that are nothing but treated trees, and to indirect lighting around homes.”

The researchers have also demonstrated that they can turn the light off by adding nanoparticles carrying a luciferase inhibitor. This could enable them to eventually create plants that shut off their light emission in response to environmental conditions such as sunlight, the researchers say.

Here’s a link to and a citation for the paper,

A Nanobionic Light-Emitting Plant by Seon-Yeong Kwak, Juan Pablo Giraldo, Min Hao Wong, Volodymyr B. Koman, Tedrick Thomas Salim Lew, Jon Ell, Mark C. Weidman, Rosalie M. Sinclair, Markita P. Landry, William A. Tisdale, and Michael S. Strano. Nano Lett., 2017, 17 (12), pp 7951–7961 DOI: 10.1021/acs.nanolett.7b04369 Publication Date (Web): November 17, 2017

Copyright © 2017 American Chemical Society

This paper is behind a paywall.