In discussions about water desalination and carbon nanomaterials, it’s graphene that’s usually mentioned these days. By contrast, scientists from the US Department of Energy’s Lawrence Livermore National Laboratory (LLNL) have turned to carbon nanotubes,

There are two news items about the work at LLNL on ScienceDaily, this first one originated by the American Association for the Advancement of Science (AAAS) offers a succinct summary of the work (from an August 24, 2017 news item on ScienceDaily,

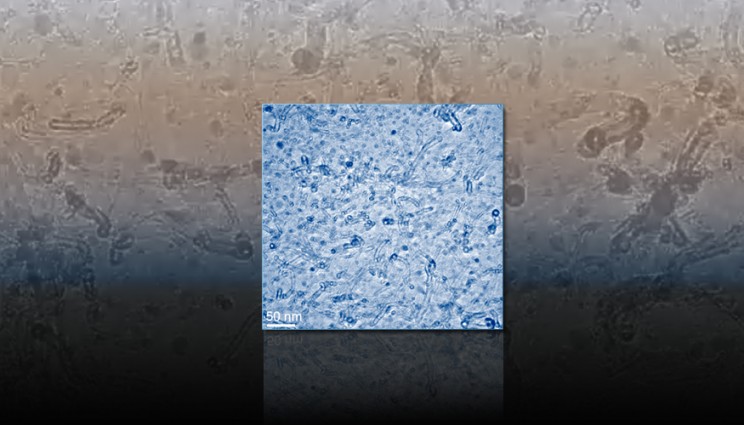

At just the right size, carbon nanotubes can filter water with better efficiency than biological proteins, a new study reveals. The results could pave the way to new water filtration systems, at a time when demands for fresh water pose a global threat to sustainable development.

A class of biological proteins, called aquaporins, is able to effectively filter water, yet scientists have not been able to manufacture scalable systems that mimic this ability. Aquaporins usually exhibit channels for filtering water molecules at a narrow width of 0.3 nanometers, which forces the water molecules into a single-file chain.

Here, Ramya H. Tunuguntla and colleagues experimented with nanotubes of different widths to see which ones are best for filtering water. Intriguingly, they found that carbon nanotubes with a width of 0.8 nanometers outperformed aquaporins in filtering efficiency by a factor of six.

These narrow carbon nanotube porins (nCNTPs) were still slim enough to force the water molecules into a single-file chain. The researchers attribute the differences between aquaporins and nCNTPS to differences in hydrogen bonding — whereas pore-lining residues in aquaporins can donate or accept H bonds to incoming water molecules, the walls of CNTPs cannot form H bonds, permitting unimpeded water flow.

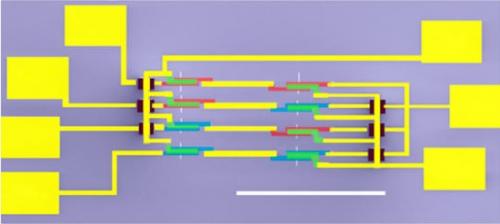

The nCNTPs in this study maintained permeability exceeding that of typical saltwater, only diminishing at very high salt concentrations. Lastly, the team found that by changing the charges at the mouth of the nanotube, they can alter the ion selectivity. This advancement is highlighted in a Perspective [in Science magazine] by Zuzanna Siwy and Francesco Fornasiero.

The second Aug. 24, 2017 news item on ScienceDaily offers a more technical perspective,

Lawrence Livermore scientists, in collaboration with researchers at Northeastern University, have developed carbon nanotube pores that can exclude salt from seawater. The team also found that water permeability in carbon nanotubes (CNTs) with diameters smaller than a nanometer (0.8 nm) exceeds that of wider carbon nanotubes by an order of magnitude.

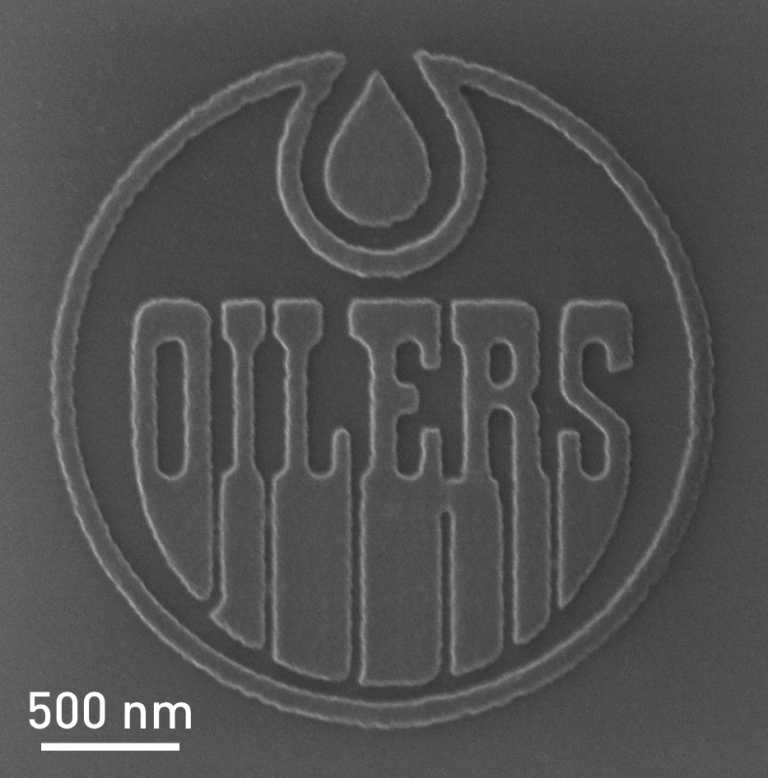

The nanotubes, hollow structures made of carbon atoms in a unique arrangement, are more than 50,000 times thinner than a human hair. The super smooth inner surface of the nanotube is responsible for their remarkably high water permeability, while the tiny pore size blocks larger salt ions.

There’s a rather lovely illustration for this work,

An artist’s depiction of the promise of carbon nanotube porins for desalination. The image depicts a stylized carbon nanotube pipe that delivers clean desalinated water from the ocean to a kitchen tap. Image by Ryan Chen/LLNL

An Aug. 24, 2017 LLNL news release (also on EurekAlert), which originated the second news item, proceeds

Increasing demands for fresh water pose a global threat to sustainable development, resulting in water scarcity for 4 billion people. Current water purification technologies can benefit from the development of membranes with specialized pores that mimic highly efficient and water selective biological proteins.

“We found that carbon nanotubes with diameters smaller than a nanometer bear a key structural feature that enables enhanced transport. The narrow hydrophobic channel forces water to translocate in a single-file arrangement, a phenomenon similar to that found in the most efficient biological water transporters,” said Ramya Tunuguntla, an LLNL postdoctoral researcher and co-author of the manuscript appearing in the Aug. 24 [2017]edition of Science.

Computer simulations and experimental studies of water transport through CNTs with diameters larger than 1 nm showed enhanced water flow, but did not match the transport efficiency of biological proteins and did not separate salt efficiently, especially at higher salinities. The key breakthrough achieved by the LLNL team was to use smaller-diameter nanotubes that delivered the required boost in performance.

“These studies revealed the details of the water transport mechanism and showed that rational manipulation of these parameters can enhance pore efficiency,” said Meni Wanunu, a physics professor at Northeastern University and co-author on the study.

“Carbon nanotubes are a unique platform for studying molecular transport and nanofluidics,” said Alex Noy, LLNL principal investigator on the CNT project and a senior author on the paper. “Their sub-nanometer size, atomically smooth surfaces and similarity to cellular water transport channels make them exceptionally suited for this purpose, and it is very exciting to make a synthetic water channel that performs better than nature’s own.”

This discovery by the LLNL scientists and their colleagues has clear implications for the next generation of water purification technologies and will spur a renewed interest in development of the next generation of high-flux membranes.

Here’s a link to and a citation for the paper,

Enhanced water permeability and tunable ion selectivity in subnanometer carbon nanotube porins by Ramya H. Tunuguntla, Robert Y. Henley, Yun-Chiao Yao, Tuan Anh Pham, Meni Wanunu, Aleksandr Noy. Science 25 Aug 2017: Vol. 357, Issue 6353, pp. 792-796 DOI: 10.1126/science.aan2438

This paper is behind a paywall.

And, Northeastern University issued an August 25, 2017 news release (also on EurekAlert) by Allie Nicodemo,

Earth is 70 percent water, but only a tiny portion—0.007 percent—is available to drink.

As potable water sources dwindle, global population increases every year. One potential solution to quenching the planet’s thirst is through desalinization—the process of removing salt from seawater. While tantalizing, this approach has always been too expensive and energy intensive for large-scale feasibility.

Now, researchers from Northeastern have made a discovery that could change that, making desalinization easier, faster and cheaper than ever before. In a paper published Thursday [August 24, 2017] in Science, the group describes how carbon nanotubes of a certain size act as the perfect filter for salt—the smallest and most abundant water contaminant.

Filtering water is tricky because water molecules want to stick together. The “H” in H2O is hydrogen, and hydrogen bonds are strong, requiring a lot of energy to separate. Water tends to bulk up and resist being filtered. But nanotubes do it rapidly, with ease.

A carbon nanotube is like an impossibly small rolled up sheet of paper, about a nanometer in diameter. For comparison, the diameter of a human hair is 50 to 70 micrometers—50,000 times wider. The tube’s miniscule size, exactly 0.8 nm, only allows one water molecule to pass through at a time. This single-file lineup disrupts the hydrogen bonds, so water can be pushed through the tubes at an accelerated pace, with no bulking.

“You can imagine if you’re a group of people trying to run through the hallway holding hands, it’s going to be a lot slower than running through the hallway single-file,” said co-author Meni Wanunu, associate professor of physics at Northeastern. Wanunu and post doctoral student Robert Henley collaborated with scientists at the Lawrence Livermore National Laboratory in California to conduct the research.

Scientists led by Aleksandr Noy at Lawrence Livermore discovered last year [2016] that carbon nanotubes were an ideal channel for proton transport. For this new study, Henley brought expertise and technology from Wanunu’s Nanoscale Biophysics Lab to Noy’s lab, and together they took the research one step further.

In addition to being precisely the right size for passing single water molecules, carbon nanotubes have a negative electric charge. This causes them to reject anything with the same charge, like the negative ions in salt, as well as other unwanted particles.

“While salt has a hard time passing through because of the charge, water is a neutral molecule and passes through easily,” Wanunu said. Scientists in Noy’s lab had theorized that carbon nanotubes could be designed for specific ion selectivity, but they didn’t have a reliable system of measurement. Luckily, “That’s the bread and butter of what we do in Meni’s lab,” Henley said. “It created a nice symbiotic relationship.”

“Robert brought the cutting-edge measurement and design capabilities of Wanunu’s group to my lab, and he was indispensable in developing a new platform that we used to measure the ion selectivity of the nanotubes,” Noy said.

The result is a novel system that could have major implications for the future of water security. The study showed that carbon nanotubes are better at desalinization than any other existing method— natural or man-made.

To keep their momentum going, the two labs have partnered with a leading water purification organization based in Israel. And the group was recently awarded a National Science Foundation/Binational Science Foundation grant to conduct further studies and develop water filtration platforms based on their new method. As they continue the research, the researchers hope to start programs where students can learn the latest on water filtration technology—with the goal of increasing that 0.007 percent.

As is usual in these cases there’s a fair degree of repetition but there’s always at least one nugget of new information, in this case, a link to Israel. As I noted many times, the Middle East is experiencing serious water issues. My most recent ‘water and the Middle East’ piece is an August 21, 2017 post about rainmaking at the Masdar Institute in United Arab Emirates. Approximately 50% of the way down the posting, I mention Israel and Palestine’s conflict over water.