The European Union’s Human Brain Project was announced in January 2013. It, along with the Graphene Flagship, had won a multi-year competition for the extraordinary sum of one million euros each to be paid out over a 10-year period. (My January 28, 2013 posting gives the details available at the time.)

At a little more than half-way through the project period, Ed Yong, in his July 22, 2019 article for The Atlantic, offers an update (of sorts),

Ten years ago, a neuroscientist said that within a decade he could simulate a human brain. Spoiler: It didn’t happen.

On July 22, 2009, the neuroscientist Henry Markram walked onstage at the TEDGlobal conference in Oxford, England, and told the audience that he was going to simulate the human brain, in all its staggering complexity, in a computer. His goals were lofty: “It’s perhaps to understand perception, to understand reality, and perhaps to even also understand physical reality.” His timeline was ambitious: “We can do it within 10 years, and if we do succeed, we will send to TED, in 10 years, a hologram to talk to you.” …

It’s been exactly 10 years. He did not succeed.

One could argue that the nature of pioneers is to reach far and talk big, and that it’s churlish to single out any one failed prediction when science is so full of them. (Science writers joke that breakthrough medicines and technologies always seem five to 10 years away, on a rolling window.) But Markram’s claims are worth revisiting for two reasons. First, the stakes were huge: In 2013, the European Commission awarded his initiative—the Human Brain Project (HBP)—a staggering 1 billion euro grant (worth about $1.42 billion at the time). Second, the HBP’s efforts, and the intense backlash to them, exposed important divides in how neuroscientists think about the brain and how it should be studied.

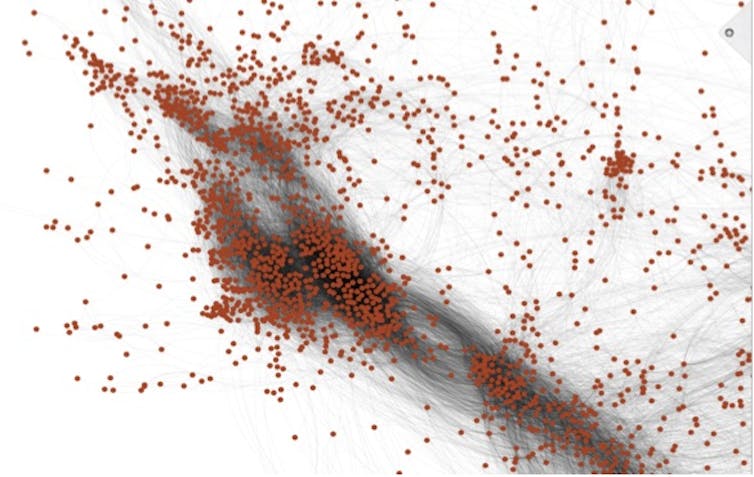

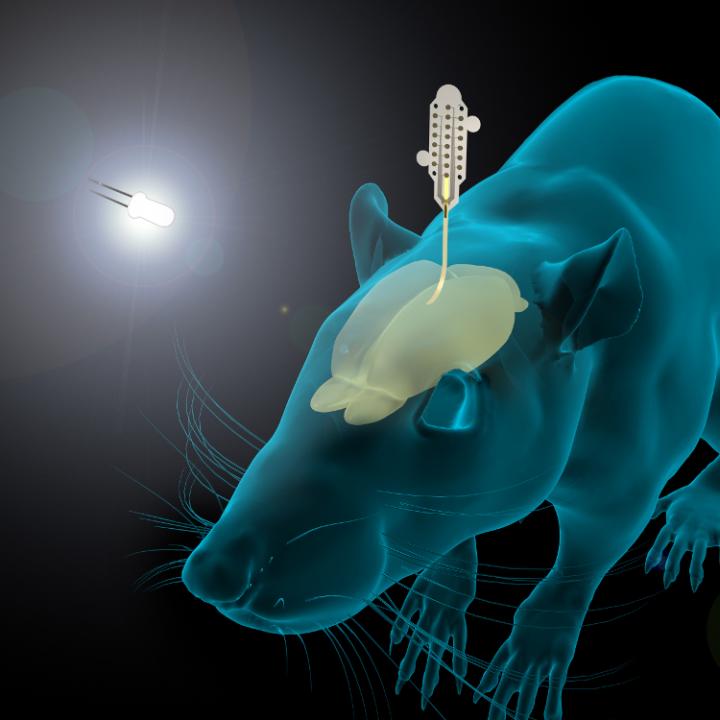

Markram’s goal wasn’t to create a simplified version of the brain, but a gloriously complex facsimile, down to the constituent neurons, the electrical activity coursing along them, and even the genes turning on and off within them. From the outset, the criticism to this approach was very widespread, and to many other neuroscientists, its bottom-up strategy seemed implausible to the point of absurdity. The brain’s intricacies—how neurons connect and cooperate, how memories form, how decisions are made—are more unknown than known, and couldn’t possibly be deciphered in enough detail within a mere decade. It is hard enough to map and model the 302 neurons of the roundworm C. elegans, let alone the 86 billion neurons within our skulls. “People thought it was unrealistic and not even reasonable as a goal,” says the neuroscientist Grace Lindsay, who is writing a book about modeling the brain.

And what was the point? The HBP wasn’t trying to address any particular research question, or test a specific hypothesis about how the brain works. The simulation seemed like an end in itself—an overengineered answer to a nonexistent question, a tool in search of a use. ……

Markram seems undeterred. In a recent paper, he and his colleague Xue Fan firmly situated brain simulations within not just neuroscience as a field, but the entire arc of Western philosophy and human civilization. And in an email statement, he told me, “Political resistance (non-scientific) to the project has indeed slowed us down considerably, but it has by no means stopped us nor will it.” He noted the 140 people still working on the Blue Brain Project, a recent set of positive reviews from five external reviewers, and its “exponentially increasing” ability to “build biologically accurate models of larger and larger brain regions.”

No time frame, this time, but there’s no shortage of other people ready to make extravagant claims about the future of neuroscience. In 2014, I attended TED’s main Vancouver conference and watched the opening talk, from the MIT Media Lab founder Nicholas Negroponte. In his closing words, he claimed that in 30 years, “we are going to ingest information. …

I’m happy to see the update. As I recall, there was murmuring almost immediately about the Human Brain Project (HBP). I never got details but it seemed that people were quite actively unhappy about the disbursements. Of course, this kind of uproar is not unusual when great sums of money are involved and the Graphene Flagship also had its rocky moments.

As for Yong’s contribution, I’m glad he’s debunking some of the hype and glory associated with the current drive to colonize the human brain and other efforts (e.g. genetics) which they often claim are the ‘future of medicine’.

To be fair. Yong is focused on the brain simulation aspect of the HBP (and Markram’s efforts in the Blue Brain Project) but there are other HBP efforts, as well, even if brain simulation seems to be the HBP’s main interest.

After reading the article, I looked up Henry Markram’s Wikipedia entry and found this,

…

In 2013, the European Union funded the Human Brain Project, led by Markram, to the tune of $1.3 billion. Markram claimed that the project would create a simulation of the entire human brain on a supercomputer within a decade, revolutionising the treatment of Alzheimer’s disease and other brain disorders. Less than two years into it, the project was recognised to be mismanaged and its claims overblown, and Markram was asked to step down.[7][8]

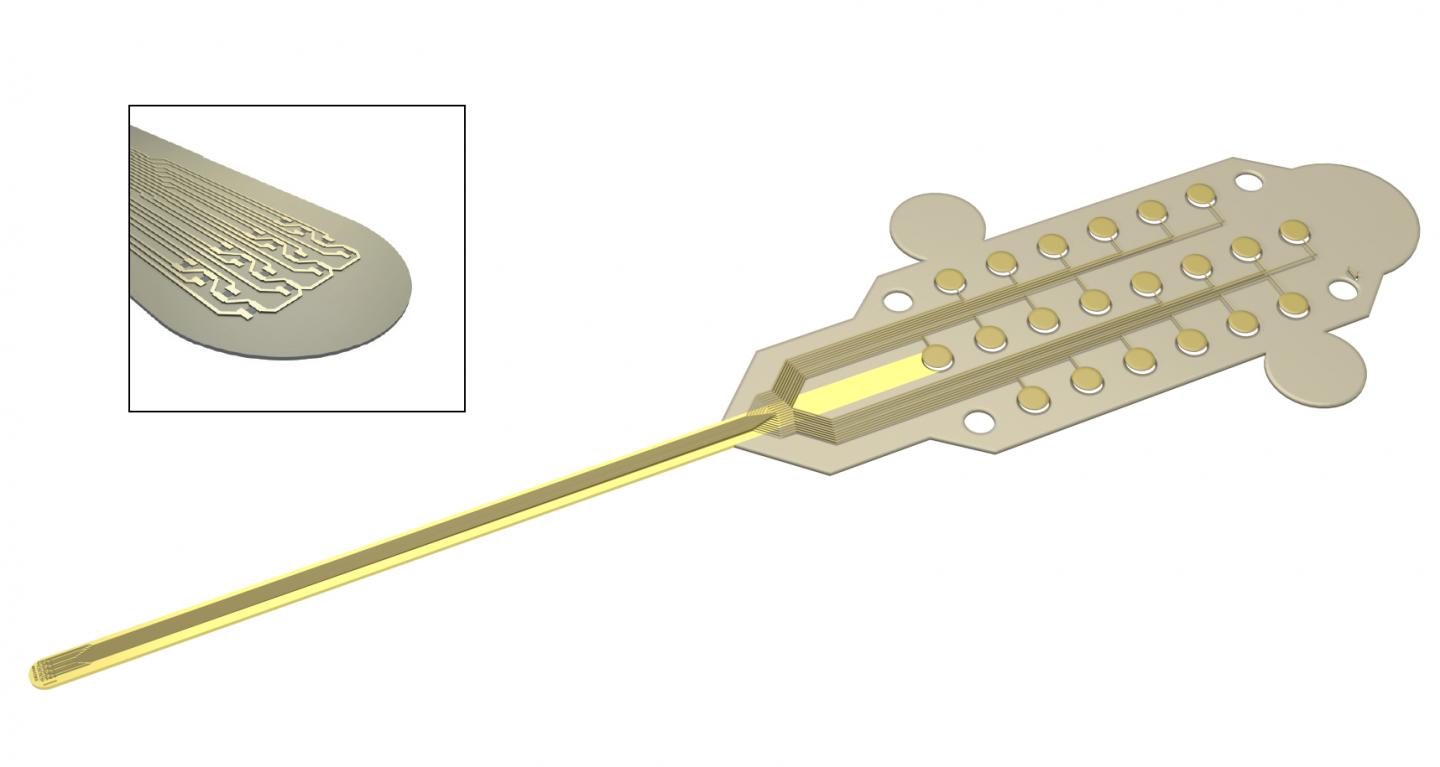

On 8 October 2015, the Blue Brain Project published the first digital reconstruction and simulation of the micro-circuitry of a neonatal rat somatosensory cortex.[9]

…

I also looked up the Human Brain Project and, talking about their other efforts, was reminded that they have a neuromorphic computing platform, SpiNNaker (mentioned here in a January 24, 2019 posting; scroll down about 50% of the way). For anyone unfamiliar with the term, neuromorphic computing/engineering is what scientists call the effort to replicate the human brain’s ability to synthesize and process information in computing processors.

In fact, there was some discussion in 2013 that the Human Brain Project and the Graphene Flagship would have some crossover projects, e.g., trying to make computers more closely resemble human brains in terms of energy use and processing power.

The Human Brain Project’s (HBP) Silicon Brains webpage notes this about their neuromorphic computing platform,

Neuromorphic computing implements aspects of biological neural networks as analogue or digital copies on electronic circuits. The goal of this approach is twofold: Offering a tool for neuroscience to understand the dynamic processes of learning and development in the brain and applying brain inspiration to generic cognitive computing. Key advantages of neuromorphic computing compared to traditional approaches are energy efficiency, execution speed, robustness against local failures and the ability to learn.

Neuromorphic Computing in the HBP

In the HBP the neuromorphic computing Subproject carries out two major activities: Constructing two large-scale, unique neuromorphic machines and prototyping the next generation neuromorphic chips.

The large-scale neuromorphic machines are based on two complementary principles. The many-core SpiNNaker machine located in Manchester [emphasis mine] (UK) connects 1 million ARM processors with a packet-based network optimized for the exchange of neural action potentials (spikes). The BrainScaleS physical model machine located in Heidelberg (Germany) implements analogue electronic models of 4 Million neurons and 1 Billion synapses on 20 silicon wafers. Both machines are integrated into the HBP collaboratory and offer full software support for their configuration, operation and data analysis.

The most prominent feature of the neuromorphic machines is their execution speed. The SpiNNaker system runs at real-time, BrainScaleS is implemented as an accelerated system and operates at 10,000 times real-time. Simulations at conventional supercomputers typical run factors of 1000 slower than biology and cannot access the vastly different timescales involved in learning and development ranging from milliseconds to years.

Recent research in neuroscience and computing has indicated that learning and development are a key aspect for neuroscience and real world applications of cognitive computing. HBP is the only project worldwide addressing this need with dedicated novel hardware architectures.

I’ve highlighted Manchester because that’s a very important city where graphene is concerned. The UK’s National Graphene Institute is housed at the University of Manchester where graphene was first isolated in 2004 by two scientists, Andre Geim and Konstantin (Kostya) Novoselov. (For their effort, they were awarded the Nobel Prize for physics in 2010.)

Getting back to the HBP (and the Graphene Flagship for that matter), the funding should be drying up sometime around 2023 and I wonder if it will be possible to assess the impact.